Craftsmanship & Quality

We are professional to make the best brushed aluminum furniture in China

Home » Craftsmanship and quality

Connection Makes A Difference.

To guarantee high quality, our strategy lies in the scientific management. Each team is responsible for their assignments. In the production process, each procedure is reported in the records. The close connections between departments has mutual influence on each other, taking quality control to the extremes.

Production: How to Make Brushed Aluminium Furniture?

The secret of producing quality products lies in our teamwork.

Cutting

Mark the start and end point to get the perfect line and size.

Drilling

Make standard holes in a steady motion with even pressure.

Brushing

Creat brushed aluminum finish by grit blasting in a safe speed. No scratch in the final look.

Bending

Hold the aluminum tight and set a desired angle to get the seamless fold.

Welding

Move at an even pace to keep the puddle a consistent size. A perfect joint includes no cracking.

Polishing

Control the grinder tight at a right angle(15°-30°) and flexible speed. Make sure to get a flat surface.

Assembling

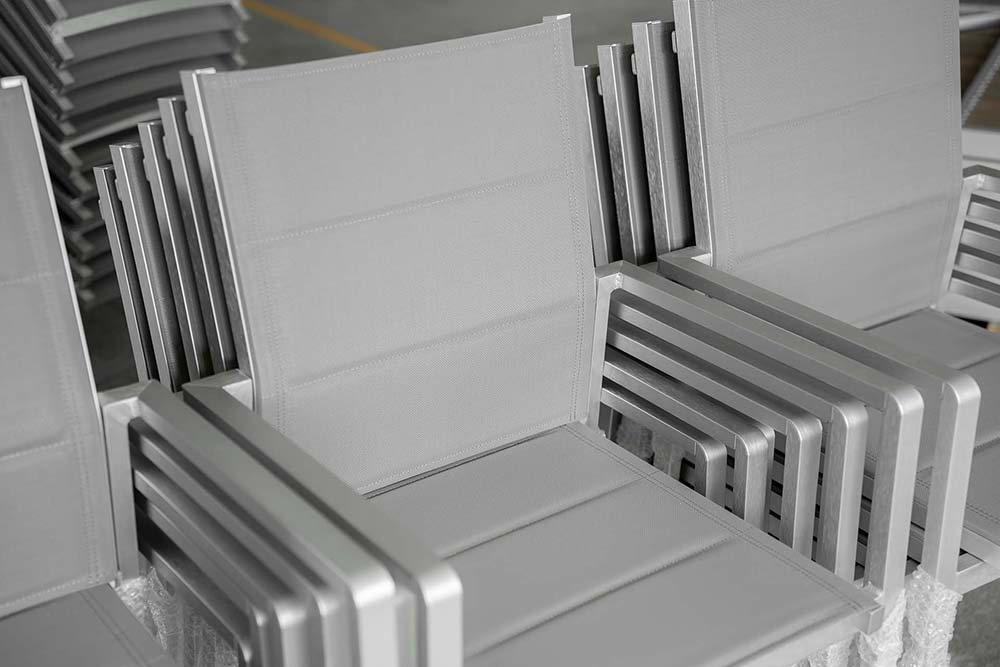

Well prepare all parts and make a standard sample first. Double check the sample before the mass production.

Packing

Check the integrity of the products and place them in order. Use polyfoam and cornerboards to guarantee the best protective packaging.

Inspectoin: Never let go easily.

Our inspection teams are perfectionists on quality. We spare no effort to keep an eye on every product by rounds of check. Our products can tell how crazy we are.

Raw Materials

Good products are made of good parts. We have professionals to find the best pick as the basis.

Finished Products

With high quality materials, we have a strict control in every manufacturing process. The final is a detail battle.